Carbon Fibre

Producing 30,000 Tons of Artificial Graphite Negative Electrode and Carbon Fiber Composite Materials Annually Project of Jilin City

1. Introduction to the Project

1.1 Project background

1.1.1 Product introduction

This project uses the special debt plant of Jilin High-tech Zone to build equipment and other production lines, mainly producing graphite negative electrode materials and high-end carbon fiber composite materials to produce carbon ceramic brake discs, high-speed rail pantograph, aircraft brake discs and other products.

Artificial graphite is obtained from petroleum coke, pitch coke, furnace coke, mesophase carbon microspheres, needle coke and other coke materials by high temperature graphitization. As a new type of carbon material, needle coke has a good graphite microcrystalline structure and a needle-like texture trend, and is an ideal carbon source for preparing negative electrode materials for lithium-ion batteries. Because of its advantages of easy graphitization, high conductivity, relatively low price and low ash content, it also has a high enough amount of lithium embedding and a good reversibility of lithium stripping to ensure high voltage, large capacity and long cycle life and current density requirements.

The tensile strength of high-end carbon fiber composite materials is generally above 3500Mpa, which is 7 to 9 times that of steel, and its density is less than 1/4 of that of steel, so it has extremely high specific strength and specific modulus. This allows carbon fiber composites to significantly reduce product weight and improve energy efficiency and operational performance while maintaining structural strength. Carbon fiber composites also have excellent heat resistance, good corrosion resistance and good thermal stability, which can maintain good dimensional stability and mechanical properties in high or low temperature environments. At the same time, carbon fiber composites also have excellent properties such as electrical conductivity, heat transfer and thermal shock resistance.

1.1.2 Market prospect

(1) Artificial graphite negative electrode market analysis

Graphite as an important non-metallic mineral, with its unique physical and chemical properties, such as high temperature resistance, thermal shock resistance, electrical conductivity, lubrication, etc., in many fields show a wide range of application value. As an allotrope of carbon, graphite has the characteristics of gray-black, opaque, stable chemical properties, etc. It is a basic mineral raw material necessary for traditional industries and strategic emerging industries. With the continuous progress of science and technology and the rapid development of new energy, new materials and other fields, the application field of graphite continues to expand, and the market demand continues to grow

Graphite industry is mainly divided into natural graphite, special graphite, artificial graphite and so on.

In recent years, the demand for graphite market has grown steadily, and the market size has continued to expand. With the rapid development of new energy vehicles, energy storage, aerospace and other emerging industries, the demand for graphite as a negative electrode material for lithium-ion batteries continues to rise.

The sales of graphite products are closely related to market demand. The rapid development of the new energy industry has promoted the sales growth of graphite products, especially in the field of lithium batteries.

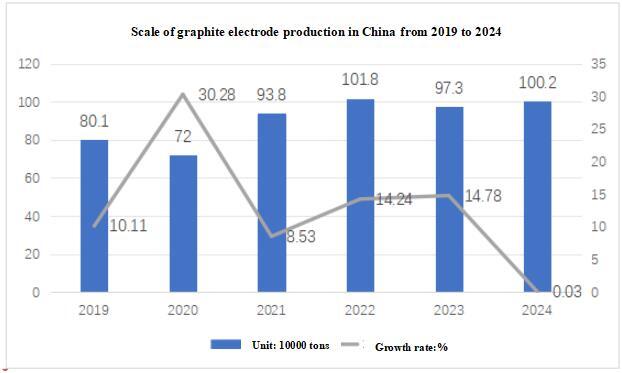

In 2019, China's graphite electrode production was 801,000 tons, and then the production showed a fluctuating upward trend, and 2024 reached 1.002 million tons. The data show that the overall output of China's graphite electrode industry is growing, reflecting the increasing demand for graphite electrodes with the development of related industries.

With the recovery of the global economy and the rapid development in fields such as new energy and new materials, the demand for graphite has been continuously increasing. According to statistics, the market size of graphite in China reached 45.167 billion yuan in 2022, with a year-on-year growth of 38.86%. It is expected that the market size of graphite will continue to maintain a rapid growth trend in the coming years. Especially with the continuous development of fields such as new energy vehicles and energy storage, graphite, as one of the important raw materials, will see an increase in demand.

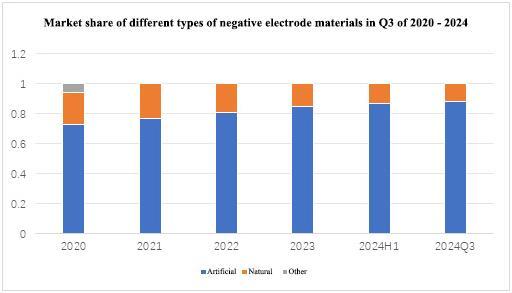

Natural graphite and artificial graphite are the two main types of current negative electrode materials, each with its own advantages. The negative electrode material industry holds an important position in the field of new energy. Currently, the demand for high-performance negative electrode materials in the market is continuously increasing.

In terms of material type, domestic artificial graphite negative electrode still holds the dominant position. The proportion of artificial negative electrode is continuously increasing, reaching approximately 88% in Q3 of 2024, setting a new record high.

The price of artificial graphite negative electrode materials continued to decline in 2024. The price of mainstream artificial graphite products with 340mAh/g capacity was lower than 16,000 yuan/ton. The market competition is intense, and enterprises need to constantly innovate and improve product quality to cope with market changes. The performance of artificial graphite negative electrode materials is constantly improving, such as improvements in energy density and cycle life, which will further promote their application in electric vehicles, energy storage systems and other fields.

(2) Analysis of the high-end carbon fiber composite materials market

Carbon fiber refers to a fiber material with a carbon content greater than 90%. It can be produced by carbonizing organic fibers such as viscose, polyacrylonitrile, and asphalt at high temperatures. High-strength and high-modulus CF is mainly formed by carbonizing polyacrylonitrile filaments at temperatures above 1000℃. When it is compounded with resins, metals, ceramics, carbon, glass, etc., it possesses high modulus, high strength, light weight, anti-fatigue, and corrosion resistance, and is widely applied in aerospace, aviation, military, marine, chemical engineering, electronics, construction, and sports and leisure fields. It is a dual-use high-tech fiber for both military and civilian purposes and plays an important role in promoting technological progress and social development.

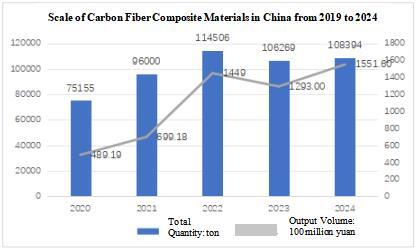

In 2023, the total output of carbon fiber composite materials in China was 106,269 tons, compared with 114,506 tons in 2022, representing a decrease of 7.2%. The output value of carbon fiber composite materials across the country in 2023 was 129.3 billion yuan, compared with 144.9 billion yuan in 2022, a decrease of 10.8%. The total output of carbon fiber composite materials in China in 2024 reached 108,394 tons, and the output value reached 155.160 billion yuan.

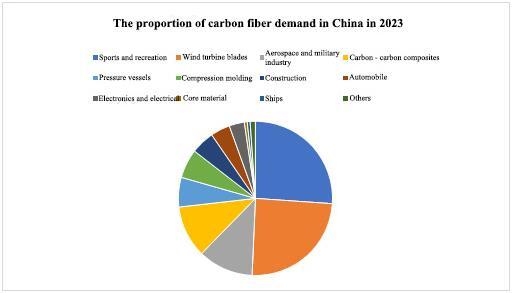

Carbon fiber, as a new type of material with outstanding performance, plays a significant role in various fields. In terms of market share, in 2023, the top three sectors in terms of demand for carbon fiber in China were sports and leisure, wind turbine blades, and aerospace and military industries, accounting for 26.1%, 24.6%, and 11.6% respectively.

At present, the top-tier enterprises in China for carbon fiber production include Jilin Chemical Fibers and Zhongfu Shenying. These enterprises have a carbon fiber raw filament production capacity of over 25000 tons and a carbon fiber production capacity of over 10000 tons. The second-tier enterprises include Jiangsu Hengshen and Guangwei Composite Materials. These enterprises have a carbon fiber raw filament production capacity of over 10000 tons and a carbon fiber production capacity of over 5000 tons. The third-tier enterprises are Tai Copper Metal Materials and Lanzhou Blue Star. These enterprises have a carbon fiber raw filament production capacity and a carbon fiber production capacity of around 5000 tons. The fourth-tier enterprises are other small and medium-sized manufacturing enterprises within the industry.

With the continuous breakthroughs in high-end carbon fiber technology in China and the development of production towards large-scale and stable scale, enterprises are gradually extending their layout to downstream application fields with higher added value. China's carbon fiber industry will gradually achieve import substitution, and the profitability of enterprises is expected to gradually recover, leading to a healthy and stable development of the market.

"Made in China 2025" has made an overall deployment for the transformation and upgrading of China's manufacturing industry and its leapfrog development. It has clarified the strategic tasks and key points for building a manufacturing power, and selected 10 major advantageous and strategic industries as breakthrough points. It aims to reach international leading or advanced levels by 2025. Among them, carbon fiber and composite materials have been included in the national key development of strategic emerging industries.

1.1.3 Technical analysis

(1) Artificial graphite negative electrode materials

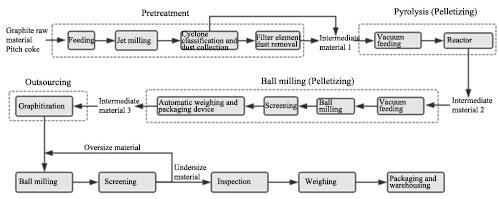

Artificial graphite is produced by crushing, granulating, graphitizing, and screening the aggregates and binders. The basic process flow is consistent, but for each enterprise's preparation process, there will be certain differences. This technical analysis is for reference only.

(2) Carbon ceramic brake discs

Firstly, mix carbon fiber powder and thermoplastic molding resin thoroughly. Then pour the mixed material into the brake disc mold. Put the mixed material into the press machine, apply pressure and heat it to 400 degrees celsius to melt the resin into plastic and make the carbon fiber powder more uniform. After cooling, take out the brake disc blank with ventilation slots and circular shapes from the mold, and then drill holes. Put the brake disc blank into a 1800-degree oven for cracking treatment to burn off impurities in the materials and make the brake discs purer. Finally, perform surface treatment on the brake discs to ensure they have good friction performance and high-temperature resistance characteristics.

(3) High-speed railway pantograph

The manufacturing process includes steps such as mold design, injection molding, mechanical processing and assembly. Mold design requires precise calculation of the dimensions and shapes of each component to ensure the accuracy and stability of the pantograph. Injection molding is used to manufacture the carbon fiber sliding plate, mechanical processing is used to manufacture the aluminum alloy frame, and finally, the components are connected together through assembly.

(4) Aircraft brake discs

The manufacturing process of brake discs involves several steps such as material preparation, processing, heat treatment, and surface treatment. During the processing, temperature and pressure need to be strictly controlled to ensure the performance and durability of the brake discs. Heat treatment and surface treatment further enhance the physical properties and anti-corrosion ability of the brake discs.

1.1.4 Advantageous conditions of project construction

(1) Policy advantageous

The National Development and Reform Commission and the National Energy Administration jointly issued the "Guiding Opinions on Accelerating the Promotion of New-type Energy Storage Development", stating that it is necessary to adhere to the diversification of energy storage technologies and promote the continuous reduction of costs and commercial-scale application of relatively mature new energy storage technologies such as lithium-ion batteries. By 2025, the transformation from the initial commercial stage to large-scale development of new energy storage should be achieved, with installed capacity reaching over 30 million kilowatts. By 2030, the comprehensive marketization development of new energy storage should be realized.

The Ministry of Industry and Information Technology and other seven departments have issued the "Opinions on Promoting the Innovative Development of Future Industries", clearly stating the development of key strategic materials such as high-performance carbon fibers, and promoting the upgrading of advanced basic materials such as non-ferrous metals, chemicals, and non-metallic minerals. The development of high-performance carbon fibers and advanced semiconductors, etc. will also be pursued.

The "Medium and Long-Term Development Plan for Civil Aviation Industry (2013-2020)" proposed to focus on developing key materials such as carbon fiber composite materials, high-performance aluminum-lithium alloys and high-strength and high-toughness steels, and to strengthen the close connection between material research and development and application assessment.

The "Several Measures for Promoting High-quality Development of Carbon Fiber and Composite Materials Industry in Jilin Province (version 2.0)" issued by Jilin Province supports the development of the carbon fiber industry. At the same time, it establishes the Jilin Province carbon fiber industry alliance and holds an innovation cooperation and exchange meeting for the high-quality development of the carbon fiber industry to provide guarantees for the carbon fiber industry.

The "Policy on Preferential Measures for the Introduction of Carbon Fiber Composite Materials and Their Products Projects in Jilin City" (Jilin Municipal Government Office Document No. 40 [2022]) supports raw material enterprises to attract downstream enterprises to invest and set up factories in Jilin through methods such as order allocation, procurement demands, and investment in joint ventures. For newly introduced enterprises, priority will be given to ensuring the supply of raw materials.

The "Policy on Incentives for the Introduction of Carbon Fiber Composite Materials and Their Products Projects in Jilin City" (Jilin Municipal Government Office Document No. 40 [2022]) stipulates that for projects falling within the scope of national strategic emerging industries, where the enterprise has fully committed its capital and completed the investment, corresponding rewards will be given based on the actual completed investment amount. For projects with an investment of 10 million yuan to 50 million yuan (inclusive), a 1% reward will be provided; for projects with an investment of over 50 million yuan to 100 million yuan (inclusive), a 2% reward will be given; For projects with an investment of over 100 million yuan, a 3% reward will be offered. The maximum reward shall not exceed 5 million yuan.

(2) Resource advantageous

Jilin City has great potential for development of resources such as hydropower, wind power, solar energy, biomass energy and oil shale. The water system in Jilin City is well-developed, with abundant hydropower resources. It is composed of some sections and tributaries of the Songhua River, Lalin River and Mudanjiang River. The annual available water resources amount to 17 billion cubic meters, which is 1.8 times the national average and 5.4 times that of cities in the north. This makes it possible to fully develop hydropower projects and also provides conditions for building large pumped storage power stations. The equivalent full-load grid-connected hours of wind power in various regions mainly range from 2,000 hours to 3,300 hours. Jilin City is located in the central part of Jilin Province. The total solar radiation in the city is between 4,800 and 5,000 megajoules per square meter, and the radiation in all regions is basically the same. The annual distribution of sunshine and solar radiation is basically consistent, with an average annual power generation time of 1,320 hours. Jilin City is an important grain production base in the province. It has abundant resources of agricultural straw and forestry processing residues, and favorable conditions for biomass energy utilization. Among them, the annual output of agricultural straw resources is 6.53 million tons and that of forestry resources is 1.5 million tons, both of which can be used for developing biomass energy. The water resources in the Songhua River Basin are abundant, and the regional geological and engineering geological conditions are stable, providing favorable conditions for the development of nuclear energy. In addition, nuclear power project sites have been selected in Xulan Liangjiashan, Jiaohe Songjiang and Huadian Dianjiangtai, and research has been conducted on the promotion of small nuclear heating reactors, laying a certain foundation for the development of nuclear energy resources.

The installed capacity of power generation facilities in the city is 6.721 million kilowatts. During the "14th Five-Year Plan" period, an additional 3.279 million kilowatts of capacity will be added, with an average annual growth rate of 8.3%. Among them: Coal-fired power generation is 3.07 million kilowatts, accounting for 30.7%; Gas-fired power generation is 860000 kilowatts, accounting for 8.6%; Wind power generation is 1.54 million kilowatts, accounting for 15.4%; Photovoltaic power generation is 700000 kilowatts, accounting for 7%; Hydropower generation is 3.5 million kilowatts (including 3.2 million kilowatts of conventional hydropower and 300000 kilowatts of pumped storage hydropower), accounting for 35%; Biomass power generation is 270000 kilowatts, accounting for 2.7%; Waste-to-energy power generation is 58000 kilowatts, accounting for 0.6%. The installed capacity of new energy and renewable energy accounts for 60.7% of the total installed capacity. It is estimated that the power generation in 2025 will be 20.63 billion kilowatt-hours, and the total transformer capacity of urban and rural power grids will reach 4891.1 megavolt-amperes.

(3) Industrial advantageous

Jilin City is regarded as the "cradle" of China's carbon fiber industry. Since the 1970s, it has been engaged in the research and production of carbon fibers. On January 2010, the base was recognized by the Ministry of Science and Technology as the only "National High-tech Industrialization Base for Carbon Fiber and Related Products" in China. In March 2020, it was approved by the Ministry of Industry and Information Technology as a "National New-type Industrialization Industrial Demonstration Base for Carbon Fiber and Composite Materials"; in September 2021, it was awarded the title of "Research and Production Base for Large-Spindle Carbon Fibers and Their Products" by the China Chemical Fiber Industry Association. Currently, the raw fiber production capacity in Jilin City reaches 160,000 tons, and the carbon fiber production capacity reaches 49,000 tons, both ranking first in China. The raw fiber production capacity ranks first globally and the carbon fiber production capacity ranks second globally, forming a relatively complete carbon fiber industrial chain. Jilin Petrochemical Company's current 200,000 tons/year low-sulfur petroleum coke production capacity provides a broad market space for the downstream industries of carbon fibers.

(4) Talent advantageous

Jilin City boasts several universities including Northeast Electric Power University, Jilin Institute of Chemical Technology, Beihua University, Jilin Agricultural Science and Technology University, Jilin Medical University, Jilin Technology College of Electronic Information, Jilin Vocational College of Industry and Technology, Jilin Railway Technology College, and Jilin General Aviation Vocational and Technical College. These universities provide continuous talent support for manufacturing enterprises. These talents not only possess rich practical experience but also have high technical levels and innovation capabilities. They can solve various technical problems during the production process, thereby enhancing production efficiency and product quality. Moreover, these professional skills talents can actively participate in the technological innovation and product research and development of enterprises, providing strong guarantees for the sustainable development of enterprises.

At the same time, Jilin City has a large number of highly qualified industrial workers. After training by enterprises and public welfare institutions, it annually supplies over 10,000 skilled talents to society and trains over 20,000 people of various types each year. The advantage of labor resources is obvious. The proportion of skilled workers among the labor force is at a relatively high level in the Northeast Urban Agglomeration. The labor force is in a period of growth dividend, with relatively low labor costs. There is a large number of highly qualified industrial workers, which can meet the needs of various enterprises.

1.2 Contents and scale of project construction

1.2.1 Scale of project construction

After the completion of the project, the capacity of negative electrode materials can reach 30,000 tons per year.

1.2.2 Construction content

The project will utilize approximately 60,000 square meters of factory buildings that have been completed in the High-tech Zone of Jilin City through special bonds. It will purchase production lines and carry out construction in two phases. The first phase will build a production line for powder modification and granulation, integrating the local graphite production capacity in Jilin and achieving a negative electrode material production capacity of 30,000 tons. The second phase will promote the industrialization of high-end carbon fiber composite materials such as carbon ceramic carbon fiber brake discs, high-speed rail pantographs, and aircraft brake discs.

1.3 Total investment of the project and capital raising

1.3.1 Total investment of the project

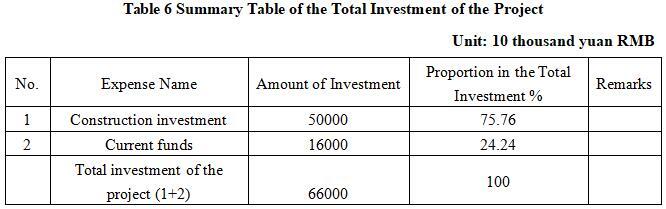

The total investment of this project amounts to 660 million yuan, among which: Construction investment is 500 million yuan and working capital is 160 million yuan.

1.3.2 Fund raising

The enterprise raises funds by itself.

1.4 Financial analysis and social evaluation

1.4.1 Main financial indexes

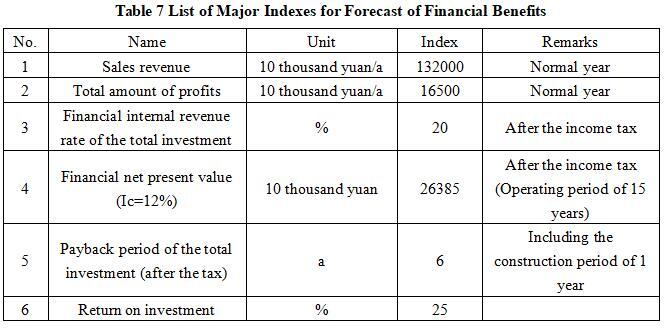

After the project reaches the production capacity, the annual sales revenue will be 1.32 billion yuan, the profit will be 165 million yuan, the investment payback period will be 6 years (after the tax, including the construction period of 1 year), and the investment profit rate will be 25%.

Note: “10 thousand yuan” in the table is in RMB.

1.4.2 Social evaluation

This project, as an important production project for lithium-ion battery negative electrode materials, will directly promote the development of the new energy vehicle industry. Lithium-ion batteries are the core components of new energy vehicles, and the quality of negative electrode materials directly affects the performance and safety of the batteries. The construction and operation of the project will have a significant promoting effect on the local industrial development, drive the development of related industries and the tertiary industry, and inject vitality into the local economy.

The project development will also strengthen the collaborative cooperation among different regions within the province, form an industrial development pattern with multiple clusters and complete industrial chain integration, and promote balanced regional economic development.

1.5 Cooperative way

Joint venture cooperation, other methods can be discussed offline.

1.6 What to be invested by the foreign party

Funds, other methods can be discussed offline.

1.7 Construction site of the project

Jilin High-tech Industrial Development Zone, Jilin Province.

1.8 Progress of the project

Planning stage.

2. Introduction to the Partner

2.1 Basic information

Name: Management Committee of Jilin High-tech Industrial Development Zone

Address: Jilin High-tech Industrial Development Zone, Jilin City

2.2 Overview

Jilin High-tech Industrial Development Zone (hereinafter referred to as "Jilin High-tech Zone") was approved by the State Council as a national high-tech zone in November 1992. After more than 30 years of development and construction, it has now developed into an ecological new urban area with a solid industrial foundation, strong innovation capabilities, and a pleasant living and working environment. It has received numerous honorary titles such as the national advanced high-tech zone and the national advanced unit for implementing the torch program.

The current jurisdiction of Jilin High-tech Zone covers an area of nearly 130 square kilometers, consisting of parts such as the South District and the North District of High-tech Zone. It presents a pattern of coordinated development between the north and the south. It has 2 sub-district offices and a permanent resident population of 160,000. There are currently over 5,000 various types of industrial and commercial enterprises, over 170 "four above" enterprises, over 140 high-tech enterprises, "specialized, skilled, innovative and new" enterprises, and technology-based small and medium-sized enterprises. There are 10 technology business incubators and 5 innovation spaces. It is a national demonstration base for mass entrepreneurship and innovation.

2.3 Contact method

Postal code: 132000

Contact person: Wang Ziming

Tel: +86-15688990008

E-mail: 67980967@qq.com

Contact method of the city (prefecture) where the project is located:

Contact unit: Investment Promotion Service Center of Jilin City Commerce Bureau

Contact person: Jiang Yuxiu

Tel: +86-432-62049694

+86-15804325460

E-mail: jlstzcjfwzx@163.com